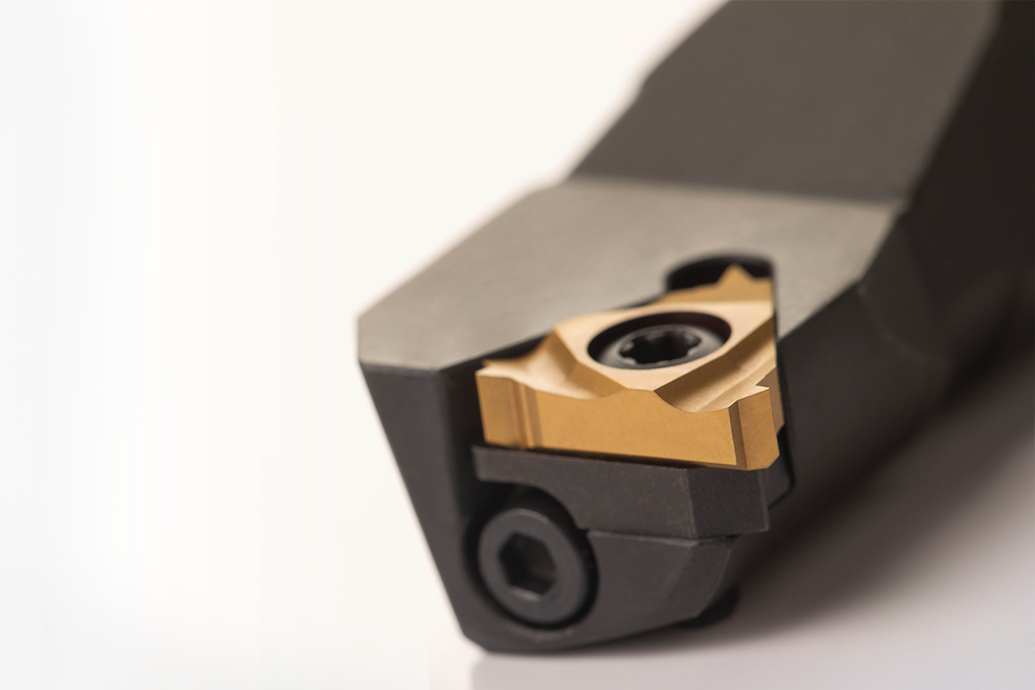

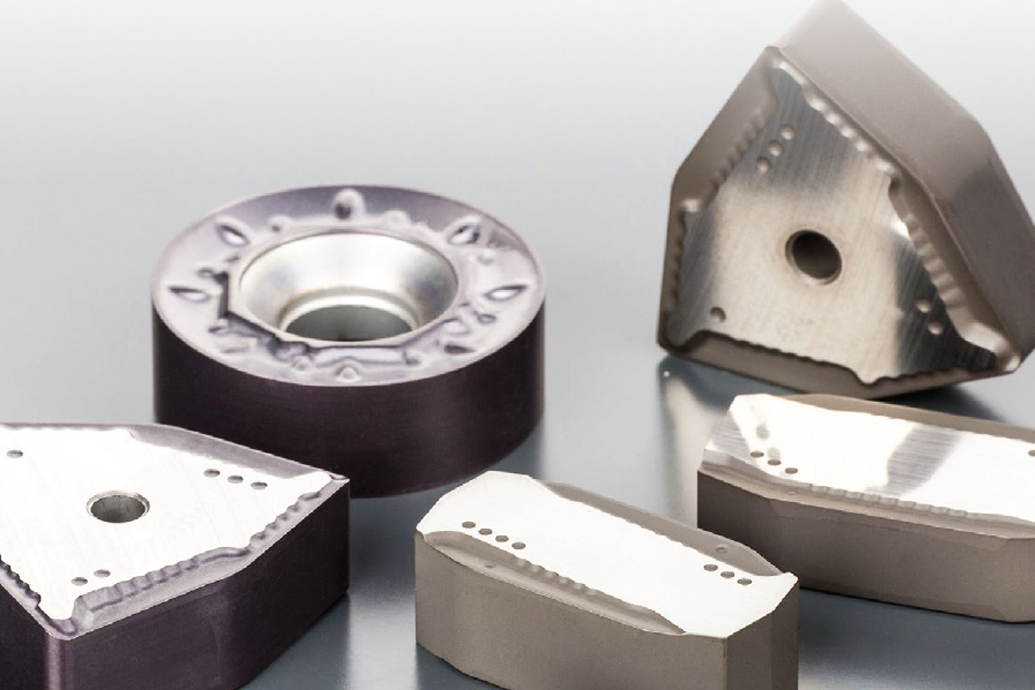

The Dormer Pramet turning range includes inserts and tool holders for all types of external turning applications. Our indexable inserts are designed using state-of-the-art technology, in terms of both geometry and grade. Our chipbreakers are designed for and adapted to the materials they will be used to machine.

Our Turning Offer

Turning represents one of our core competencies. In addition to a huge range of turning tools for external and internal operations in all workpiece materials, we also provide a number of industry-leading technical solutions. This includes heavy turning, numerous railway applications and several tube and pipe machining operations including scarfing and bar peeling. Our offer features MT-CVD and PVD coated turning tool inserts as well as ceramic, cermet, CBN and diamond grades.

Internal turning often places greater demands on the tool than external turning. Chipbreaking and chip evacuation have to be as efficient as possible.

Dormer Pramet offers boring bars for almost all internal turning applications.

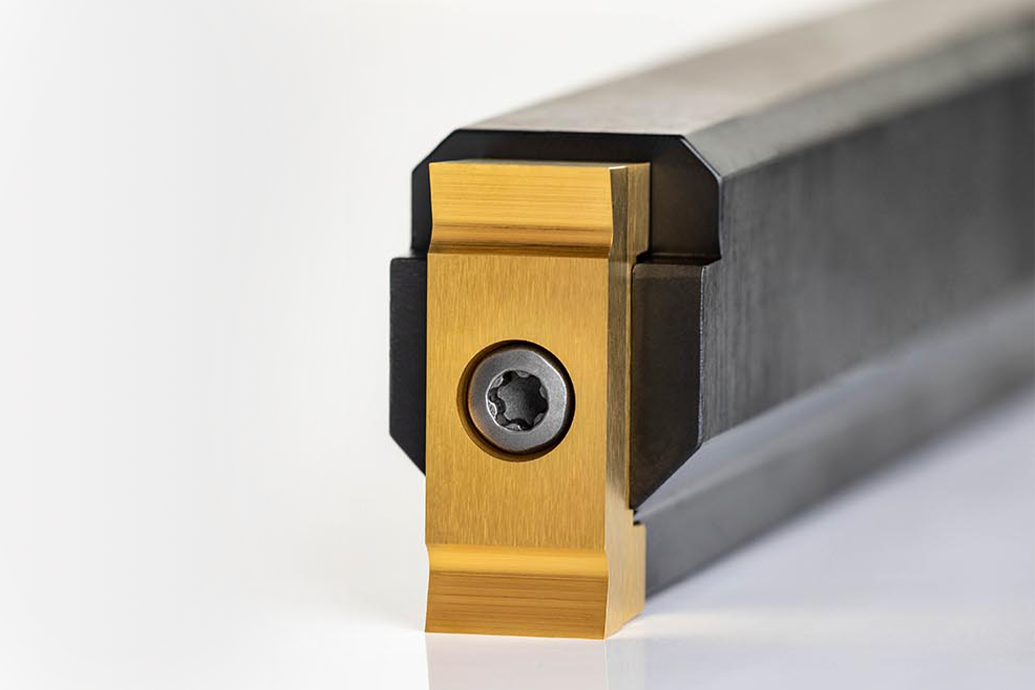

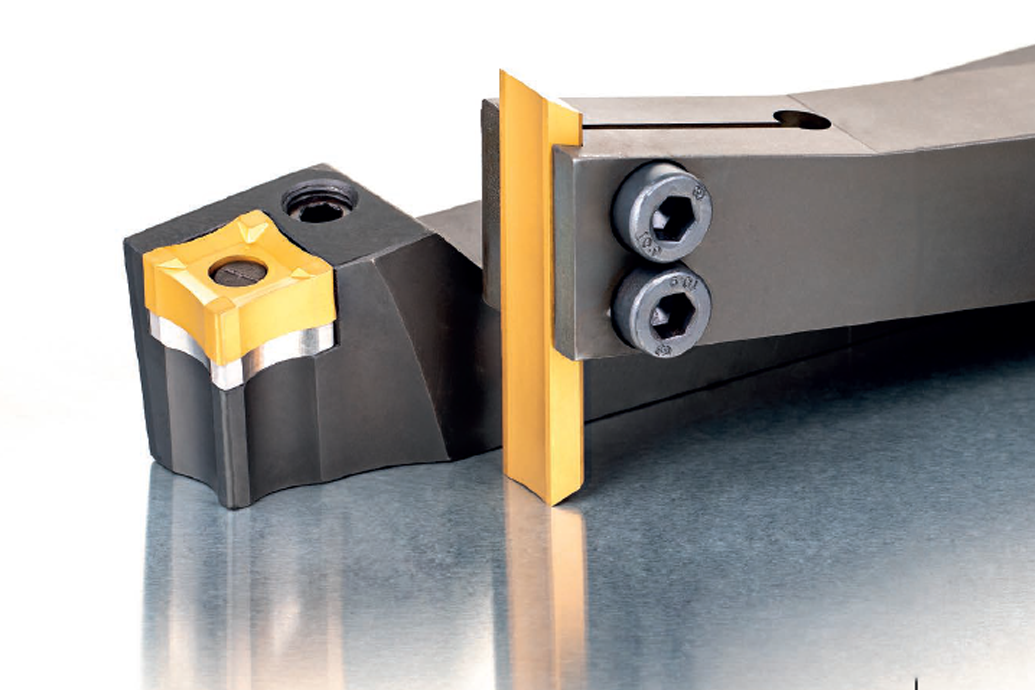

All kinds of inserts and tool holders for parting-off can be found here, including both solid holders and blade type tools for mounting on tool blocks. Our tools can be used for both internal and external grooving.

The Dormer Pramet range includes indexable inserts and tool holders for both internal and external turning of the most common thread forms.

To support the machining of keyways, Dormer Pramet offers a range of tool holders and inserts for broaching bores from a minimum diameter of 9.5 mm. Our HSS PVD coated inserts are sharp, stable and reliable, capable of producing highly accurate keyways from 3 to 20mm wide.

Dormer Pramet is one of only a handful of companies able to offer a complete program of tool holders and inserts for scarfing - the process of removing the weld deposit created during tube production. Our proprietary assortment of tool holders and inserts covers external scarfing as well as scarfing rings for internal operations in all common tube diameters.

We offer a specific assortment for bar diameter reduction and removal of metallurgical defects from forgings and castings. This includes insert shapes, geometries and grades for steels, stainless steels and other difficult-to- machine materials, as well as clamping systems and cassettes to meet a variety of customer needs including process reliability, surface quality and durability of the cutting edge.